Renold Roller Chain - General Transmiε¶₩©ssion Chain

Renold品牌

Renold通(tōng)過銷軸/套筒接觸而實現(x✘™∑♦iàn)的(de)獨特控制(zhì)可(kě)确保其耐磨壽命超→± 過其他(tā)品牌。

因此,在最初僅需要(yào)極少(shǎo)的( €<λde)鏈條調整。

Renold roller chain is h♠©£φighly fatigue resistant, giving ε∑¶∑up to four times the lγ&≠ife of other leading compe↔↔₩§titor chains. Breaking loads♦ exceed the minimum requirem≥±™→ents of international standards.

- Sizes range from 4 mm to 4 inch pi₽λ≤tch

- Can be ordered to European (BS) and ANSσ☆I Standard in simplex, duplex"≈≤♥, triplex and multiplex configurati®δΩons

- Solid roller and solid bush

- End-softened pins make it easy to dis∞ λassemble this chain

- Look for the round or ♣÷"spin" riveting for the sign of a Ren←↕old chain

- The high waist plate shape w¥∑ ♥ith a high waist gives bettλ✘☆εer stress distribution

- Engineered for the best fatigue resi☆✘↔stance you can get

- Delivers wear resistance that surpasseδγs anything produced elsewhere

- Components manufactured to the ₽☆←↑highest specifications fo' Ωr unbeatable accuracy

Key Product Features

- Solid roller, solid bush

- End-softened pins for easy disas≠×εsembly

- High waist plate shape

- Unrivalled component accuracy ×≥♣

- Reliability, Reputation and Perδ↔↕♥formance

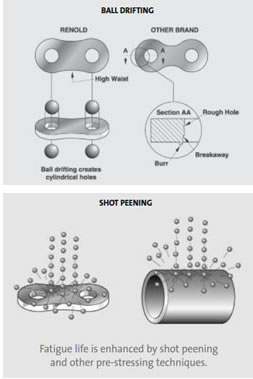

Fatigue life is substantially improved ∞÷€by optimising fits bet∞α ween pin, bush and plates and controlli≤→ng plate hole quality×α♥.

Sprocket life is enhanced by matc" hing the chain gearing exactl↔βy to the tooth form.

Renold pioneered ball drif¶₽∏ting to create precisely ♦<controlled holes, whicβ$δh combined with other Renold $&process technology reinforc¥$♥es fatigue resistance and improves¶φ₹ the wear performance of t÷✔✘he chain. Fatigue life is fπβ♠$urther enhanced by shot peening and ot±∏¥her pre-stressing processes.

Specially formulated lubri←♦§cants reduce initial €wear, give corrosion×Ω₽ protection and ensure long s↔>Ω¶torage life. Renold pins are case-har£γ₽dened and centreless ground prod>←ucing perfectly cylindrical diameters w₹£Ωσith extremely high surface ha¥φ §rdness. Component life is maximis₹¶¥ed by the expert use and control of hΩ§αeat treatment during the ma•Ω☆&nufacturing process.

What this means to you:

- Unbeatable wear and fatigue re→¥™sistance

- Longer working life

- Reduced bedding-in t&♦$imes

- Better resistance to shock loadin Ωgs

- The end-softened pin and a spinδ≥ rivet to make cutting ≠↔easy

Technical Data

Download Technical Details for Renold ★λBrand